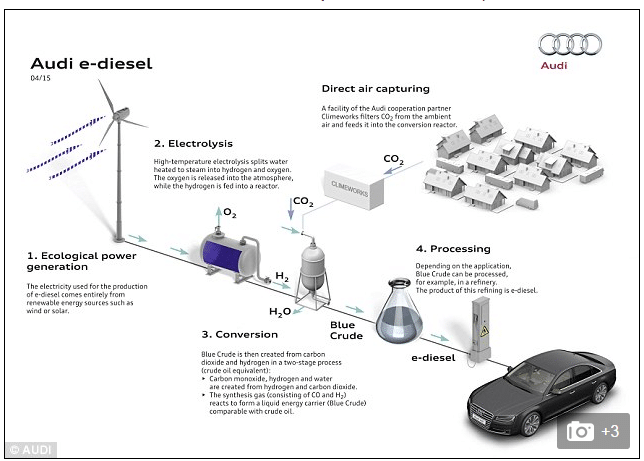

To make the fuel, water is first heated to form steam, which is then broken down into its constituent hydrogen and oxygen using high-temperature electrolysis. By performing this process at temperatures above 800°C (1,472°F), the water breaks down with greater efficiency than at room temperature. The hydrogen is then pumped into a reactor with carbon dioxide at high pressure and high temperatures. This causes them to react to produce long-chained liquid hydrocarbons. Hydrocarbons are the basic building block of all fossil fuels but the compounds produced in the reactor are known as ‘blue crude’. Audi mentions the whole process can be powered using renewable energy and can be achieved with an efficiency of around 70 per cent. The blue crude which can be refined in such a way to standardize crude oil to produce e-diesel Now Sunfire, says the fuel was highly combustible and produced less pollution than traditional diesel “The engine runs quieter and fewer pollutants are being created,” Sunfire’s Christian von Olshausen said. A special processing plant has been built in Dresden Reick and is set to produce 3,000 litres of e-diesel in the coming months. “If we get the first sales order, we will be ready to commercialize our technology”, said Sunfire CTO The new fuel was tested by German Education and Research minister Johanna Wanka last week. She put the first five litres into her official car, and declared the project a success. “If we can make widespread use of CO2 as a raw material, we will make a crucial contribution to climate protection and the efficient use of resources, and put the fundamentals of the green economy in place,” she said. ‘If we can make wide usage of carbon dioxide as a raw material, we will definitely make use of the resources, and put the essentials of the “green economy” in place.’ We wish the best, cleanest technology win